Blog

A practical supplier management programme – Three key building blocks

By Mark Webb |

“11% of the value identified in category management leaks away due to poor contract and supplier management.”

Many organisations take an ad-hoc approach to supplier management, with activities being undertaken inconsistently across internal teams and suppliers.

At the most fundamental level this results in the savings generated during Category Management activities not being realised. The Future Purchasing 2016-17 Global Category Management Survey demonstrated that an average 11% of initial savings secured ‘leaked-away’ during the life of the subsequent contracts.

There are three key factors in preventing such leakage.

A business case for investing in supplier management

Whilst the need to prevent leakage of savings generated through category management is instinctively recognised, securing the required investment is always dependent on a quantitative business case.

The most common rationale we see being used is the realisation of identified category management savings. With annual category management savings typically in the 8-11% range, this presents a substantial financial prize to lose for most organisations. This approach was used by a global oil major, where the business case for supplier management was based on securing all savings promised plus an incremental 1% savings from total contract spend of suppliers in scope.

Other business case sources include reductions in supply chain risk, enhancing productivity and incremental revenue through increased supplier innovation.

A central team to drive change

Building a supplier management process and educating procurement and business stakeholders is a key part of the roll-out of supplier management. However, there is a need to drive a broader programme of change to embed the process and most organisations establish a small central team within the procurement function to achieve this.

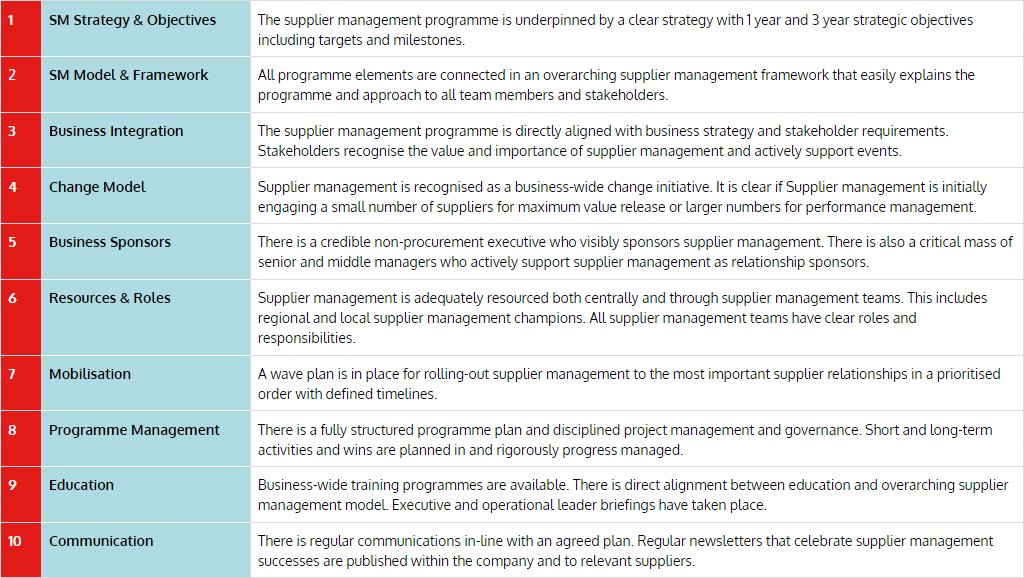

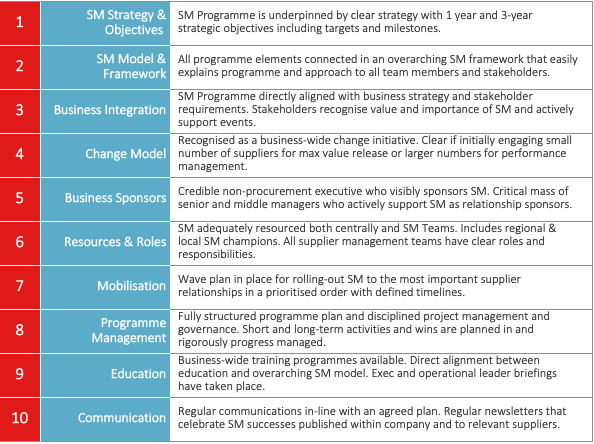

The table below summarises typical responsibilities of a central supplier management team.

A high-level supplier management framework

Supplier management is a more complex process than category management, as it consists of a number of discrete activities. These are often undertaken in parallel and often by a range of people from different functions within a business. This challenge is amplified when a typical organisation matrix is overlaid and different business units, geographies, contracts and supplier structures are taken into account.

This complexity makes it crucial to establish a simple framework to represent the supplier management process. This is a key tool for explaining the different elements of the process at a high level.

The example model below shows five key components and summarises the main activities to be completed in each. At the next level of detail, how-to guides and templates should be available to ensure efficiency and consistency of application across supplier relationships. The process should be flexible so that it is used more intensively with the most important suppliers identified in annual segmentation activities.

Benchmark your category management capability

Future Purchasing can help you to confirm the scale of additional benefit available to your organisation by optimising category management

We can compare you against world class performance and confirm what you need to change in order to optimise Category Management and advance to the next level of performance.

We facilitate a high energy 2-3 hour workshop with your procurement leadership team. The output from the workshop is clarity on current strengths and weaknesses, along with a prioritised list of practices areas to improve and initial recommendations on how to achieve the improvements – all summarised in a clear action plan.

Further reading

Blog post: Global Supplier Management Skills Building Programme including Stakeholder Engagement Workshops

About Mark Webb

Managing Director

30+ years procurement experience in line management

and consulting roles.

Previous employment: Price Waterhouse, Mobil Oil and QP Group

Education: BSc in Management Science and MSc in Business by Research, Aston University

CIPS: Member

Further Reading

Case study

Global Supplier Management Skills Building Programme including Stakeholder Engagement Workshops

10/12/2019

Read More

Webinar

A Meeting of Minds Webinar

18/07/2024

Watch

Case study

AstraZeneca

At AstraZeneca the foundations of category management are built on stakeholder engagement

07/11/2023

Read More