Blog

Supplier performance – Supplier gone rogue

By Mark Hubbard |

At what point does the performance of a supplier suggest we need to take definitive action with our SRM?

From our experience, we see a whole range of responses to inadequate supplier performance from different organisations, ranging from full intervention to full inaction, even when there appear to be compelling reasons for mobilising a well-designed intervention.

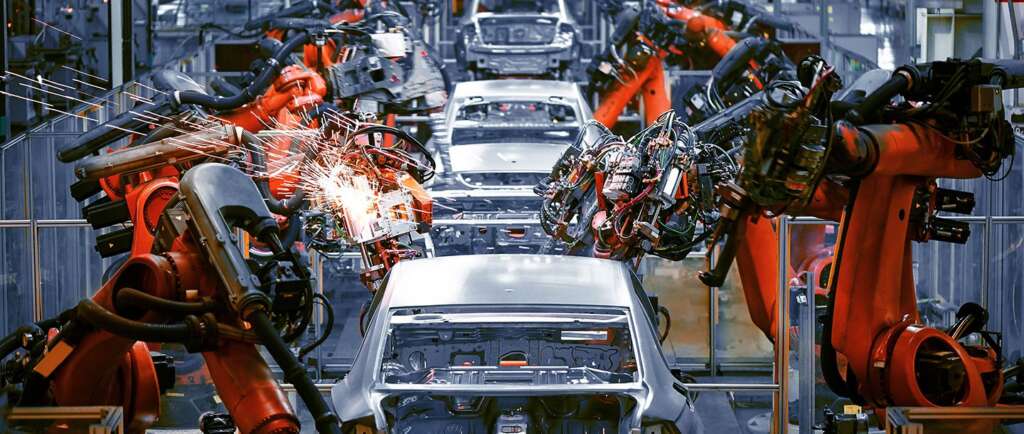

Interestingly, the approach seems to depend on how advanced supplier development activity is in a particular business, and some sectors are more advanced than others. The automotive industry has led the field in this area and spends more time on supplier development than many others, being entirely happy to work on detailed interventions whenever necessary (although still preferring suppliers to get there by themselves).

In these more developed areas, the trigger can be small changes in measured performance in key areas of SRM, delivery performance issues breaching certain thresholds, quality issues breaching defined targets. In other sectors, we have seen non-delivery over many months, not triggering any detailed actions at all.

So, the initial question is, what level of supplier performance should trigger a more detailed intervention? Perhaps the way to look at this is more about considering the level of resource available to develop corrective actions and make sure that help is targeted into the most required element of supplier performance. There are never enough resources to do everything, so making sure that assessing where interventions should be directed becomes important.

This suggests an underlying systems-based approach will be needed, tracking the key performance indicators across a series of critical suppliers. In turn, this indicates that a good understanding of KPI’s is necessary to allow the systems to track the right parameters.

This is now sounding like an investment in many different areas. So, what is the benefit of this activity?

Demonstrating the benefits from intervention is often hard, as measuring the full benefit is not only focused on the areas affected.

It is rare for a complete picture of the consequential effects of late delivery to be developed, as it is both complex and varies from case to case. For example, spending time with a supplier working on delivery issues can be considered a pure cost, merely delivering the thing that should have turned up anyway. However, non-delivery or late delivery costs are often masked – slowdowns in programs, knock-on effects elsewhere, time spent chasing and expediting, increased load when products do turn up, increased ‘safety stock levels and their associated costs and more.

So taking a holistic view of the benefits of investment in supplier performance improvement makes sense. That said, we see in many industries where the actual performance of suppliers is a matter of speculation, not fact.

So, what should we do? It is worth looking across supplier performance regularly and targeting interventions in agreed areas, particularly if the implied costs of poor performance look significant. Setting up a regular review panel, targeting resources, and testing for improvements is an excellent way to start.

More advanced users of the approach use smaller indicators of poor performance and aim to prevent the issues from becoming severe (rather than waiting for a catastrophic failure to trigger an action).

We can help you with this and other aspects of Supplier Relationship Management. Moving in that direction is a journey that should be planned for and managed. We’re often working in that interface between category management and SRM.

About Mark Hubbard

Director

30+ years experience in procurement and supplier management, in line and consulting roles

Previous employment: Positive Purchasing Ltd, SITA,

QP Group, BMW, SWWS, Rover

Education: BSc in Engineering Metallurgy, MBA University of Plymouth

CIPS: Member